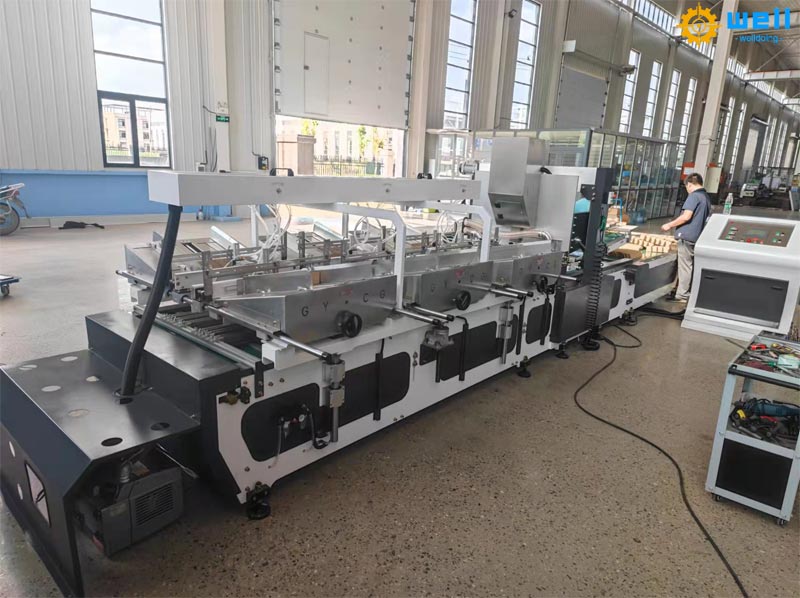

Cleaning the partition assembler machine requires a combination of daily maintenance and deep cleaning. The specific steps are as follows:

1、 Daily cleaning

Surface cleaning: After daily work, use a dry cloth to wipe off dust and oil stains on the surface of the machine, with a focus on cleaning dust prone areas such as conveyor belts and grid insertion mechanisms.

Internal paper debris cleaning: If there is paper debris residue on the equipment, turn off the power and open the side cover. Use a vacuum cleaner or soft brush to remove paper debris from key areas such as pins and tracks to avoid accumulation and affecting accuracy

two.

2、 Deep cleaning and lubrication

Cleaning of moving parts: For components such as pins and paper feeding rollers, special tools (such as knives) should be used to remove paper jams or deformation residues, and the wear condition should be checked.

Lubrication and maintenance: After cleaning, add lubricating oil or butter to the transmission components such as bearings and chains to ensure smooth operation (such as lubricating the paper feeding track gears once a month).

3、 Electrical system maintenance

Dust removal of control box: Regularly clean the inside of the electrical control box with a dry cloth to avoid short circuits caused by dust, and check whether the circuit connections are firm.

Sensor inspection: Clean the surface of the photoelectric sensor to ensure that it can accurately detect the position of the cardboard.

4、 Precautions

Power off during cleaning to avoid mechanical misoperation.

Avoid using a damp cloth to directly wipe the circuit board, and use a balloon to remove accumulated dust.

The above steps can effectively keep the Automatic partition inserter machine clean, extend its service life, and reduce the failure rate.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975