The production mode of High speed paper edge board making machine mainly revolves around efficiency, precision, and automation, combined with modern technology to achieve continuous operation from raw materials to finished products. The following are its core production mode and technical characteristics:

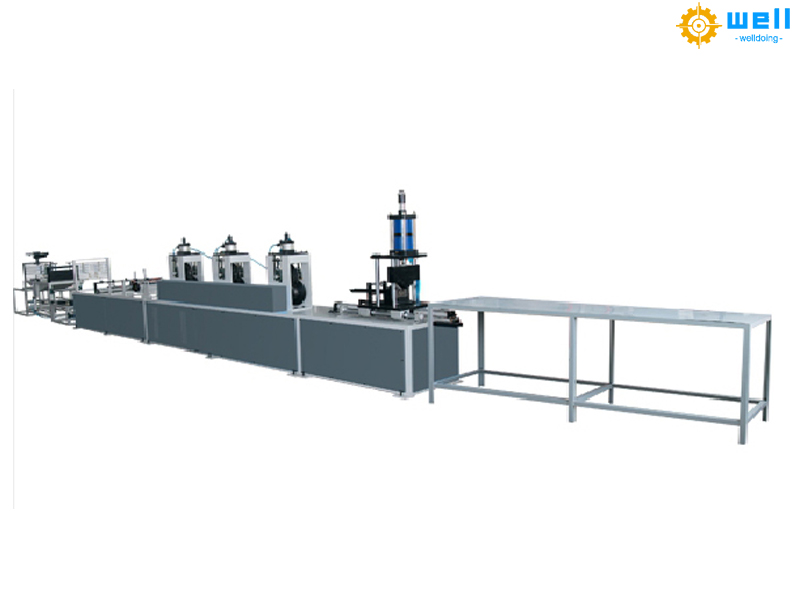

1. Automated production line process

Fully automatic paper edge protector machine usually consists of corner protector forming machine, bonding machine, cutting machine, etc. It is controlled by PLC (programmable logic controller) and servo motor to achieve synchronous operation of feeding, bending, bonding, cutting and other processes.

2. Precise control technology

Electronic cam technology: used in punching and cutting processes to ensure accuracy error control within ± 1.5mm at high speeds (such as 40 meters/minute), avoiding paper breakage or cutting problems.

Multi axis synchronization system: By using photoelectric sensing devices and pneumatic components, the positioning error of the corner guard is achieved between 5-15mm, improving the placement accuracy.

3. Intelligent and energy-saving design

Human Machine Interface (HMI): Touchscreen operation supports real-time adjustment of parameters such as length, speed, etc., reducing the need for manual intervention.

Energy saving configuration: Some equipment adopts an air pressure system to adjust the tightness of the corner protector, reducing energy consumption, and supporting temperature control heating system to optimize the bonding effect.

4. Integration of supporting equipment

Fully automated production is often combined with winding machines, packaging machines, etc. to form a packaging assembly line. For example, a vertical corner protector can simultaneously place four corner protectors, which can be reinforced with a horizontal belt tying machine to improve overall efficiency.

5. Customization and Scalability

The Kraft Paper Corner Board Machine supports customized processing, such as replacing the pressure wheel to produce unequal sided corner protectors, or optionally installing a flatbed head to achieve multi use on one machine.

Typical Equipment Examples

Corner protector forming machine: The fully automatic corner protector supports cutting, forming, and cutting integration, with a delivery cycle of about 30 days.

Compression tester: used for quality inspection of finished products, such as the compression tester of Dexiang Instrument, which can switch multiple units and output thermal reports.

The fully automatic paper corner protector, through high integration and intelligent control, significantly reduces labor costs while meeting diverse production needs. It is a key equipment for the packaging industry to achieve green and efficient development.

cording to the width of the paper to ensure smooth output, avoid wrinkles or offset, and provide stable raw material supply for subsequent processing.

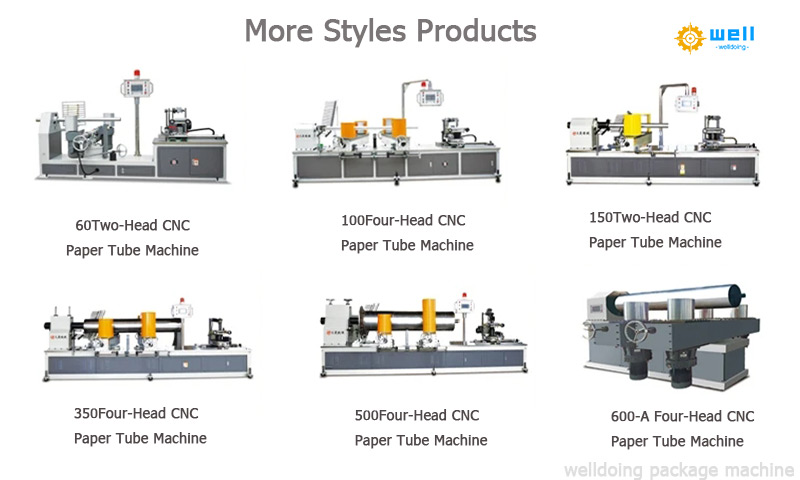

The Paper Tube Core Making Machine 's glue coating device is responsible for evenly applying adhesive on the surface of the paper. By contacting the roller with the paper, the adhesive is transferred to the designated position on the paper surface. The amount of adhesive applied can be controlled by adjusting the device. Excessive adhesive can easily cause deformation of the paper, while insufficient adhesive can affect the bonding strength of the paper tube, directly affecting the firmness of the paper tube.

The winding mechanism is the core component of paper tube forming, consisting of a spindle and a winding mold. The paper is guided backwards and wrapped around the mold, and the main shaft drives the mold to rotate, causing the paper to be stacked layer by layer and tightly wound. The size of the mold determines the inner diameter of the paper tube, and the pressure during winding can be adjusted to ensure that the paper tube is tightly formed.

The cutting device is used to cut continuously wound paper tubes into a set length. By contacting the paper tube with a high-speed rotating blade, the cutting action is completed. The cutting position is controlled by a positioning mechanism to ensure a smooth cut and reduce the generation of burrs, meeting the production needs of paper tubes of different lengths.

The transmission system provides power to various components, connected to gears, belts, and other transmission parts through motors, coordinating the speed of unwinding, winding, cutting, and other processes to ensure consistent rhythm and avoid paper breakage or poor paper tube forming caused by mismatched speeds.

These components work together and function independently, forming the production system of the Spiral paper tube winding machine and providing reliable support for the mass production of paper tubes.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975