Lead edge feeder printing die cutting slotting machine :

1. Designed according to the high standard and reliable function.

2. Main motor frequency convert to control.

3. All the drive rollers adopted high quality steel materials, hard chromiumplating and the surface treated by lapping finish.

4. Driving gear: 40Cr alloy, gas azotizing and precise made.

5. The main drive roller adopt keyless connect, decrease the connection gap, guarantee the printing precision.

6. Lubricate oil automatic balance device, keep the equal oil level equal in each unit.

7. The Full automatic box printer slotter rotary die cutter machine adopt PLC control, with utomatic zero return and emories function.

8. Use lead edge feeder for feed the cardboard. No table lift and down while work, it is easy to work for the bent and thin paperboard.

9. Customer can choose use steel anilox roller or ceramic roller, the lines of the anilox roller ac so can be chosed according to the customer requirement.

10. Option: Rorary die-cutter, rotary slotter.

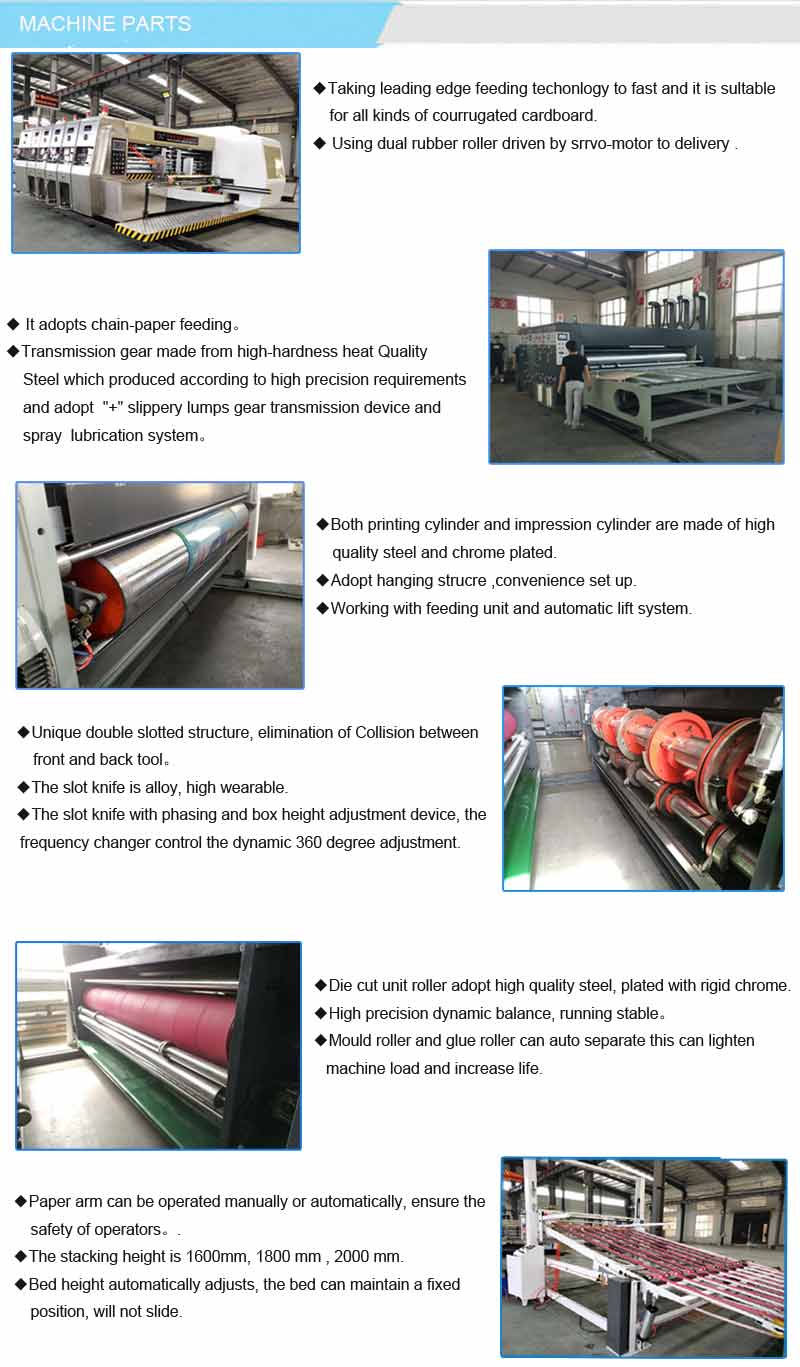

Leading edge paper feeding printing die-cutting equipment main structure and its description

| Name | Description |

| Lead Feeding part | Feed paperboard automatically |

| Printing part | Flexo printing Print the colour you want , max colour is 6 |

| Slotting part | This part is for standard carton box making |

| Die cutting | This part is for customized carton box making(We can also do mould according to customer's box design ) |

| Stacker part | Finished cardboard will be auto stacker by this machine |

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975