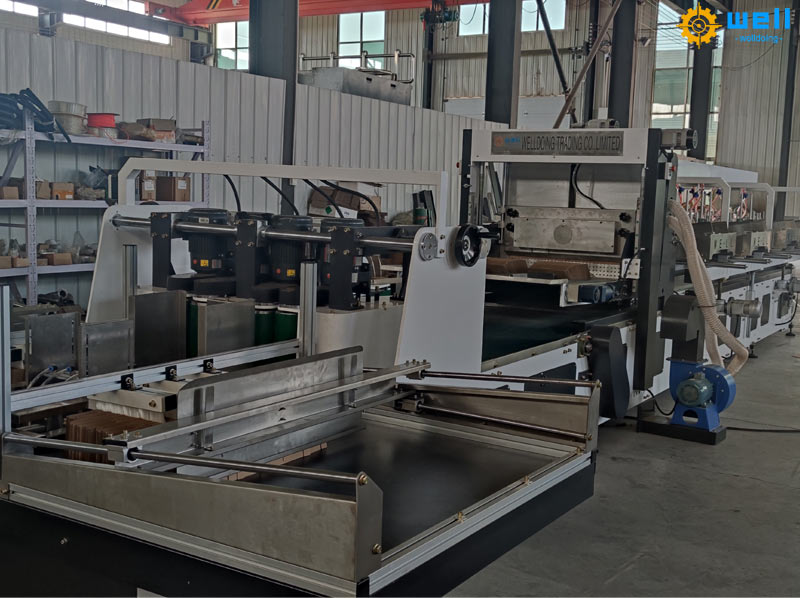

The paper cardboard partition assembly machine is an efficient equipment in the packaging industry, with its core advantages of high automation, precision and efficiency, and multi-functional adaptation, which can greatly improve production efficiency and packaging quality.

Corrugated box partition assembly machine core functional advantages include:

Automated production: The entire process from paper feeding to grid insertion is automated, reducing manual intervention and significantly improving efficiency.

Precise control: Advanced control system is adopted to ensure that the size and folding angle of each partition are consistent, ensuring the regularity and protection of the packaging.

High speed and efficiency: Optimized with dual workstation design to achieve double efficiency and meet the needs of large-scale production.

Multi functional adaptation: capable of processing partitions of various shapes and sizes, suitable for multiple industries such as food, electronics, healthcare, and industry.

In terms of application, Automatic partition assembler machine is particularly suitable for:

Food and beverage: protect product integrity, such as separating yogurt and juice bottles.

Electronic products: provide precise internal buffering protection for precision components.

Medical packaging: meets hygiene requirements and safely separates drugs and devices.

Industrial products: Separate and protect mechanical components and other industrial products.

There are various equipment options in the market, ranging from economical to high-end fully automatic models. Choose the cardboard grid machine that suits you.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975