The intelligent process of the Hardboard production line is deeply integrated with automation and digital technology, significantly improving production efficiency and product quality. Its core process and technical characteristics are as follows:

1、 Full process automation control

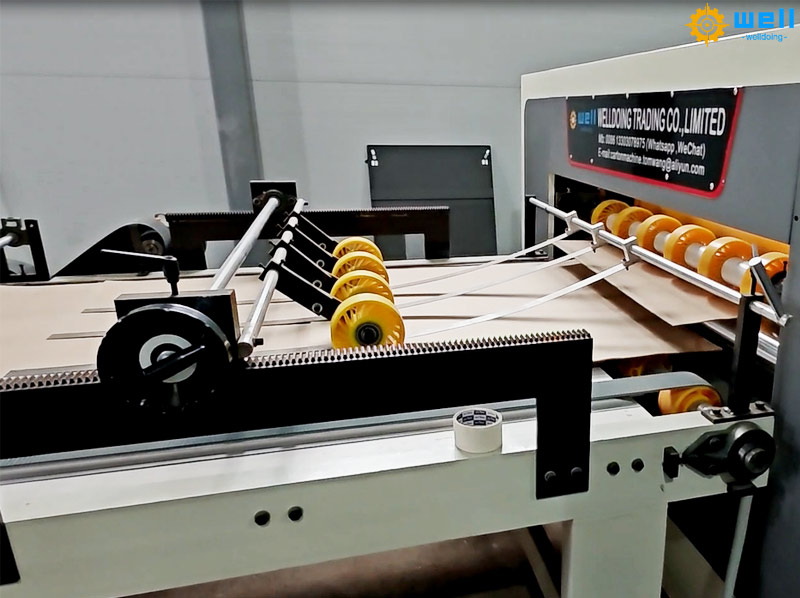

Intelligent feeding system

By adopting the linkage technology of conveyor belt and drum line, automatic positioning and transmission of cardboard substrate are achieved, with an error controlled within ± 0.5mm, reducing manual intervention.

Dynamic tension adjustment

Real time monitoring of tension fluctuations in the roll paper through servo motors, combined with PID algorithm to automatically adjust the traction speed, ensures the flatness of the substrate.

2、 High precision printing and molding of the cardboard production line

Flexographic printing technology

Using water-based ink and resin plate, supporting complex pattern printing, color difference Δ E ≤ 1.5, while reducing VOCs emissions.

Intelligent die-cutting system

Equipped with a visual positioning device, it can automatically identify the position of the die-cutting plate and correct it, reducing the mold changing time to 180 seconds and supporting quick switching between multiple specifications.

3、 Data driven production optimization

MES system integration

Real time collection of equipment operation data (such as temperature, pressure, speed), predicting faults through AI analysis, reducing unplanned downtime by 30%.

Intelligent management of energy consumption

Dynamically adjust motor power based on production load, reducing unit energy consumption by 15% -20%.

4、 Intelligent packaging in the later stage

Automatic palletizing robot

Using a six axis robotic arm and 3D visual guidance, the stacking accuracy reaches ± 1mm and supports irregular stacking of cardboard boxes.

Quality closed-loop testing

Through infrared sensors and image recognition technology, parameters such as cardboard thickness and adhesive strength are detected online, and the automatic rejection rate of defective products exceeds 99%.

5、 Flexible production adaptation

By using digital twin technology to simulate the production process of technology Grey board making machine, it supports rapid scheduling of small batch customized orders, reducing the time for changing orders by 60% compared to traditional production lines.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975