The core advantages of the ink waste water treatment equipment industry are reflected in technical adaptability, economic efficiency, and environmental benefits. The following is a specific analysis:

1、 Technical advantages

Efficient processing capability

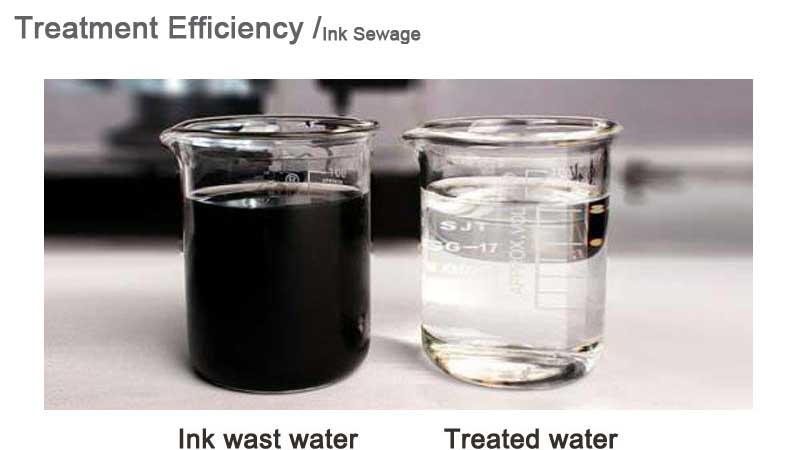

The combination of AO biological treatment process and push flow biological contact oxidation tank significantly improves the removal rate of organic matter compared to traditional fillers, and the effluent quality is stable and meets the national first-class A standard. MBR membrane technology further enhances the retention efficiency of suspended solids and pathogens, making it suitable for high standard reuse scenarios.

Intelligent management

The waste water treatment equipment is equipped with a fully automatic control system and remote monitoring function, which can adjust operating parameters in real time and warn of faults, reducing the need for manual intervention. For example, decentralized integrated equipment simplifies operation and maintenance management in rural areas through automated processes.

2、 Economic advantage

Save construction and operation costs

The integrated equipment can be installed underground, reducing the investment in civil engineering and pipeline network, and reducing the initial investment by 30% -50% compared to traditional sewage treatment plants. The low sludge production design (such as the sludge production of the biological contact oxidation tank being only one-third of that of the activated sludge process) further reduces disposal costs.

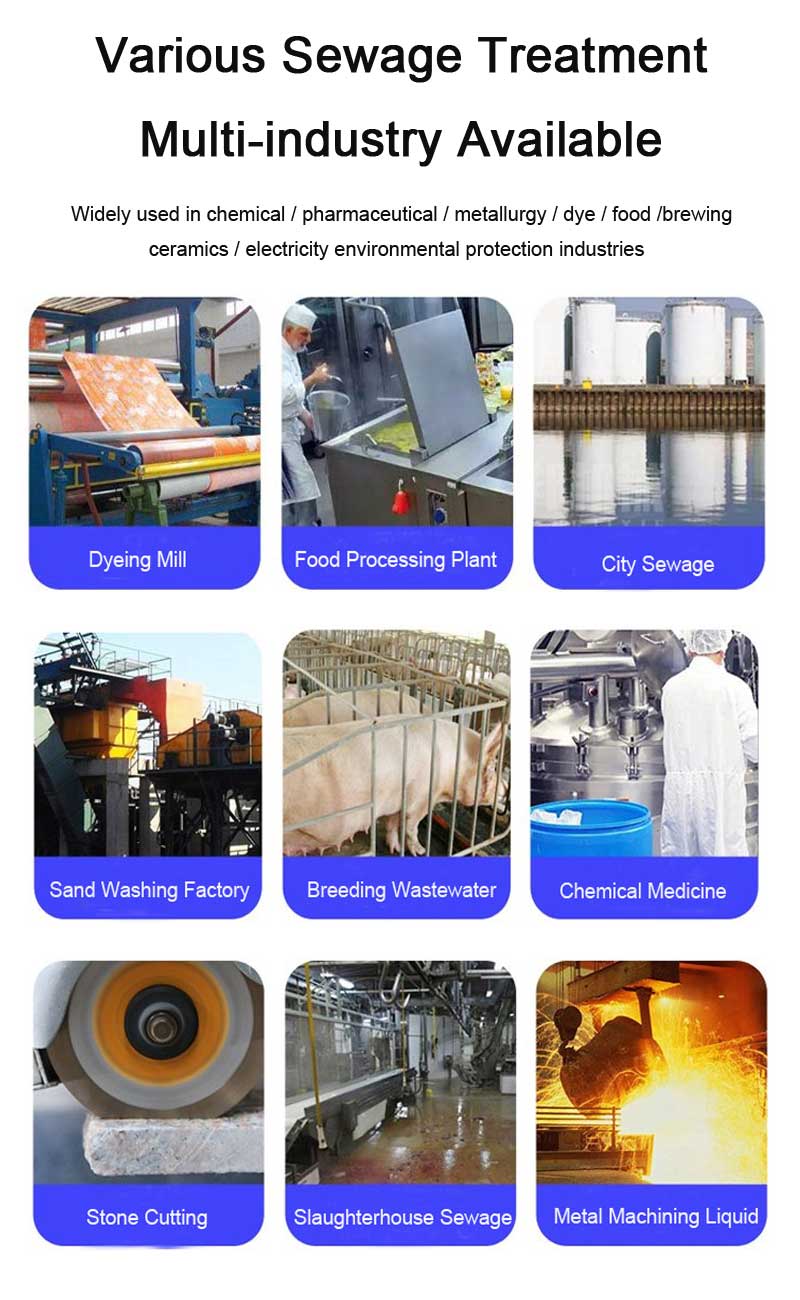

Flexible adaptation to different scenarios

Modular design supports mobile deployment and is suitable for dispersed scenarios such as resorts and high-speed service areas, without the need for large-scale renovation of existing facilities.

3、 Environmental Protection and Social Benefits

Resource recycling and utilization

The treated water quality can be reused for greening or industrial cooling, alleviating the problem of water scarcity. Some flexo ink wastewater treatment machine integrates soil deodorization facilities, which reduce secondary pollution by decomposing odors through microorganisms.

Policy driven development

The tightening of environmental policies has promoted technological innovation, such as government subsidies and tax incentives, which have accelerated the popularization of low-energy equipment (such as vibration MBR).

4、 Industry Trends

Technological integration: Combining nanomaterials (such as graphene adsorbents) with biological processes to enhance the efficiency of heavy metal removal.

Market expansion: The demand for rural sewage treatment is increasing, and decentralized equipment has become a new growth point.

Overall, the industry has achieved a balance between efficiency, low cost, and sustainable development through technological iteration and scenario adaptation.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975