The maintenance of automatic sewage treatment machine is the key to ensuring its long-term stable operation and extending its service life. The core requirements include regular inspection, lubrication, cleaning, and timely replacement of vulnerable parts, while also paying attention to the status of the control system.

Daily maintenance is the foundation, and it is necessary to conduct hourly inspections to observe whether the equipment has abnormal vibrations, noise, or odors, and to check whether the current, voltage, and temperature of the motor and fan are normal. The grid well should be cleaned once a day to avoid blockage. In non abnormal situations, the equipment should be placed in "automatic" mode, and the fan should be started regularly after shutdown.

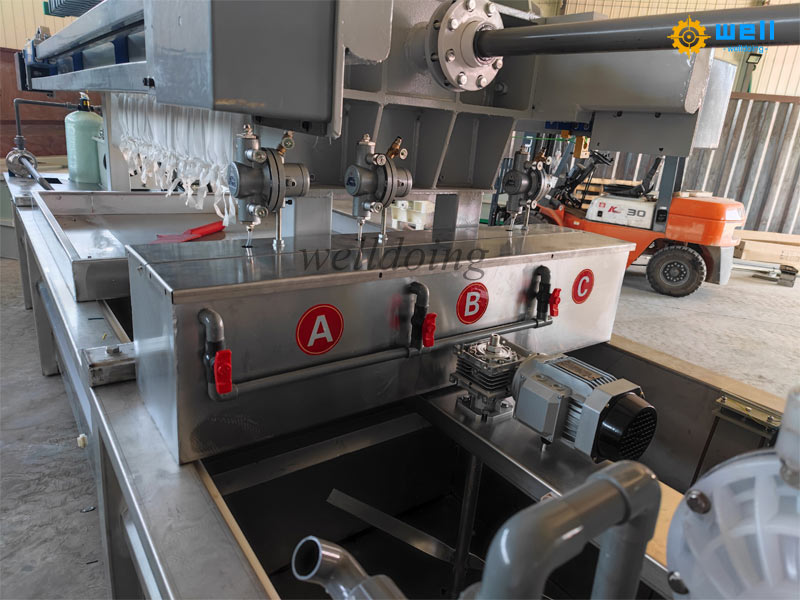

Regular maintenance is more in-depth. The automatic Flexo ink wastewater treatment machine needs to clean the air filter, start the sludge pump for half an hour, clean the Y-shaped filter and sand filter tank every week. Every June, it is necessary to replace the drive belt, motor bearings, sealing rings, and activated carbon in the carbon filter. For fans, it is necessary to regularly check the oil level in the fuel tank, clean the oil filter, and inspect the condition of the air filter and V-belt.

Lubrication and corrosion prevention are equally important. All pumps, fans, and other equipment should be regularly refueled or oil replaced. Generally, fans and submersible pumps need to be maintained once after running for 8000 to 10000 hours. At the same time, it is necessary to regularly inspect all components of the equipment for wear, corrosion, or damage, especially vulnerable parts such as the impeller and seals of the water pump.

The maintenance of the control system cannot be ignored. Regularly check whether the electrical components in the PLC control cabinet of the automatic industrial sewage treatment equipment are loose, maintain the temperature in the cabinet at 0-55 ℃ and the relative humidity below 85%, and regularly clean the dust. When the equipment alarm light is on or beeps, it is necessary to promptly troubleshoot and not operate with a fault.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975