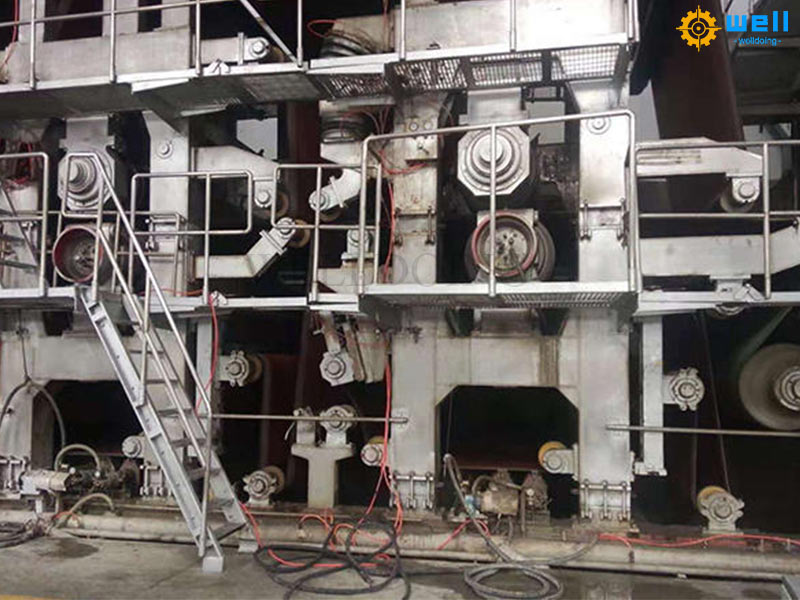

The automatic Kraft paper making machine is a combination of a series of supporting equipment. The production process is generally as follows: the pulp material is transported to the front flow box of the paper machine production line through the sizing flow system, and then the pulp flow is separated through the mesh, press, front dryer, rear press, rear dryer, calender, and paper winding machine to become the raw paper; The raw paper can also be separately fed into the machine for coating and rewinding to produce finished paper.

The safe operation of paper machines requires collaboration and cooperation from all aspects, starting from different aspects to maximize the production safety of paper machines.

Firstly, when starting up the Corrugated paper making line for production, it is necessary to ensure timely lubrication of the lubrication parts, safe and stable operation of different components after starting up, and timely resolution of problems. This is the most basic. Secondly, attention should be paid to the entry points of the rollers and mesh cages, the entry points of the rollers and drying cylinders, the entry points of the cold cylinder for winding paper, and the entry points of each rotating guide roller. These are all places where problems are prone to occur, and production safety needs to be taken into account. The most important thing is to operate the paper machine production line safely.

FAQ

1. Are you a factory or trading company?

2. What is the terms of payment you accept?

We usually accept the T/T payment, we need 30% of total amount as deposit,pay the 70% balance before delivery, but we can also accept the L/C.

3. How does your factory do regarding quality control?

Quality is priority. We always regard great importance to quality controlling from the very small thing(even a small screw we will choose the best quality) from the beginning.

4. How is the packaging of the product?

5. We don't know how to operate the machine, how to deal with it?

We can send our engineers to your site and train your employees. You only need to bear the air tickets, accommodation, food and transfer expenses of our engineers in your country.

WELLDOING TRADING Co. Ltd. is a manufacturer + sales and after-sales company, which is mainly engaged in large-scale semi-automatic chain-bar water-based printing machine, automatic flexo ink printing slotting die cutting machine, high-speed high-definition paper box printing and slotting die-cutting machine, 2 layers corrugated production line, box-sticking machine, paper tube making machine, flexo ink printing wastewater treatment machine and so on.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975