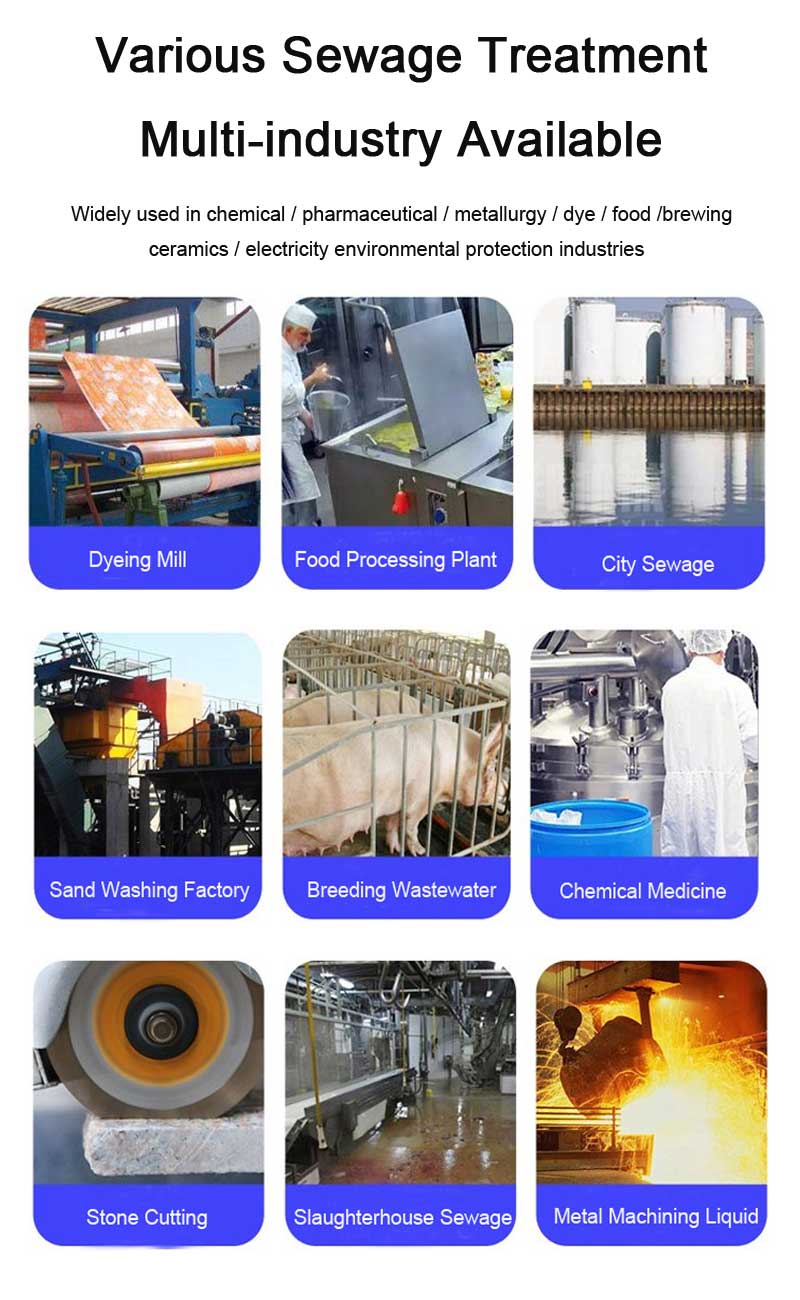

dyeing Sewage treatment machine is an environmental protection device dedicated to treating high chromaticity and high concentration organic wastewater discharged from the textile printing and dyeing industry. Its core functions include removing COD, BOD, chromaticity, and difficult to degrade organic matter, ensuring that the effluent meets the "Textile Dyeing and Finishing Industry Pollutant Discharge Standards" or reuse requirements.

technical process of the sewage water treatment machine

Composite processing technology

Biological treatment: Adopting a combination process of hydrolysis acidification and biological contact oxidation, anaerobic bacteria and aerobic bacteria work together to degrade organic matter, and the treatment effect on difficult to degrade substances such as PVA slurry and alkali reduction wastewater is significant.

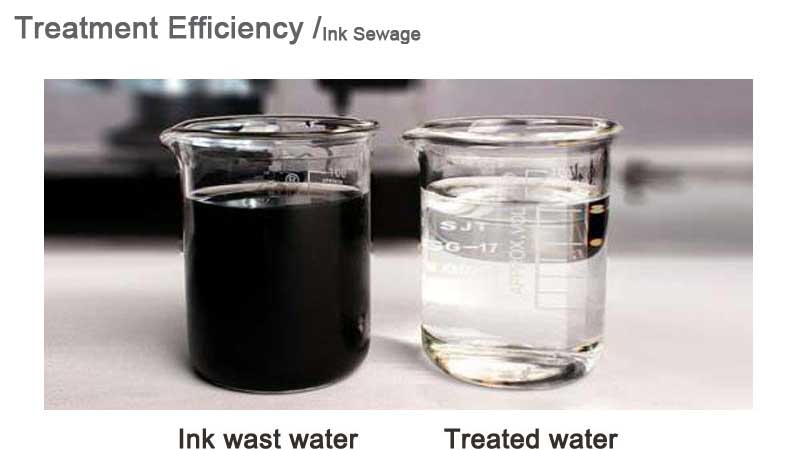

Physical and chemical enhancement: Dissolved air flotation, activated carbon adsorption, and Fenton oxidation technologies can improve the color removal rate (up to 90% or more), and some equipment integrates MBR membrane bioreactors to achieve sludge reduction.

Emerging technologies: electrolysis air flotation method reduces energy consumption through microporous titanium based electrodes, and the COD removal rate can reach 20% -30% when treating acidic/alkaline dye wastewater; The flow carbon method combines activated carbon adsorption and microbial regeneration to achieve deep decolorization.

Modular design

Some waste water treatment machines are equipped with intelligent control systems that support dynamic parameter adjustment to adapt to water quality fluctuations, such as the biological aerated filter (BAF), which reduces energy consumption by 15% -30% by optimizing aeration volume.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975