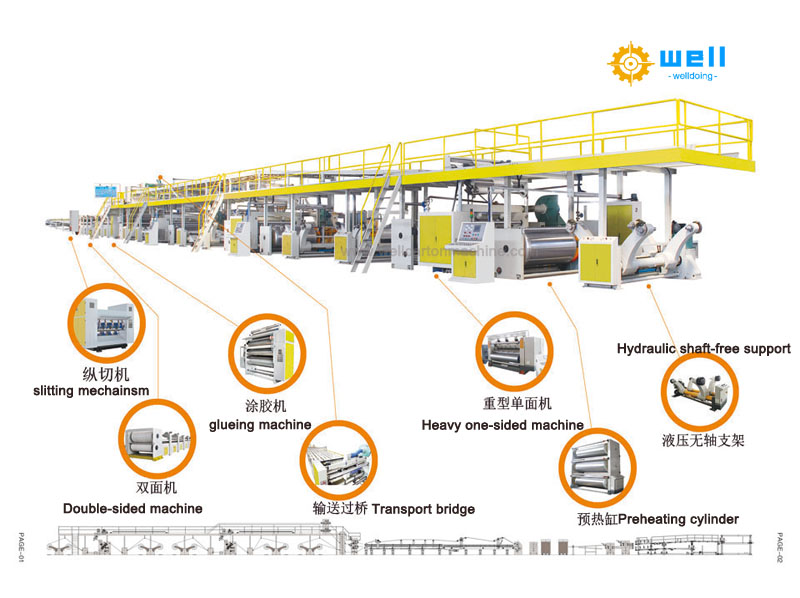

The seven layer corrugated board production line adopts the energy-saving mode, and the high-temperature heat transfer oil is used for providing a heat source to the whole machine, the heating energy of the steam is more than 60 percent, the energy consumption is greatly reduced, the production cost is effectively reduced.

The seven-layer automatic corrugated paperboard production line is suitable for mass automatic production, can produce the excellent corrugated board meeting the national standard, the production efficiency is high, the quality of the paper board is good, the centralized control is adopted, the operation is simple and convenient, the maintenance is convenient, the safety is safe and reliable, and the labor intensity of workers is greatly reduced.

The seven-layer corrugated board production line adopts the current international latest energy-saving mode, the high-temperature heat transfer oil is used for providing a heat source to the whole machine, the steam heating energy is saved by more than 60 percent, the energy consumption is greatly reduced, the production cost is effectively compressed, And is suitable for large and medium-sized paper box factories to be used.

The temperature and pressure of seven-layer Corrugated board production line play an important role in the production process of corrugated board. In the process of baking channel composite paperboard, it is particularly important. The adhesive we use now is starch raw glue, and raw glue acts on two objects without adhesion. How to make raw glue react to mature glue must be helped by temperature. Someone once did an experiment: put raw glue in one container, warm the water in the other container, put the container with raw glue in another container, and stir in a container with raw rubber. When the temperature rises to 63 ℃, the raw glue is gelatinized. This experiment shows that in order to change the raw glue into the mature adhesive, it must reach a certain temperature, otherwise it is impossible to make the raw glue completely gelatinized, and without the thoroughly gelatinized adhesive, it can not have the ideal bonding effect. The raw glue is usually used in the middle of the two kinds of paper, the temperature of the hot plate can be transferred to the bonding point through one or more layers of paper, so the surface temperature of the hot plate must reach 170 ℃ when the production speed is less than 80 m / min (the faster the speed is, the higher the temperature is). If the surface temperature of the hot board does not gelatinize the raw glue at the bonding point of the paperboard, the moisture will be absorbed quickly by the paper, which will result in the decrease of the bonding strength of the paperboard.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975