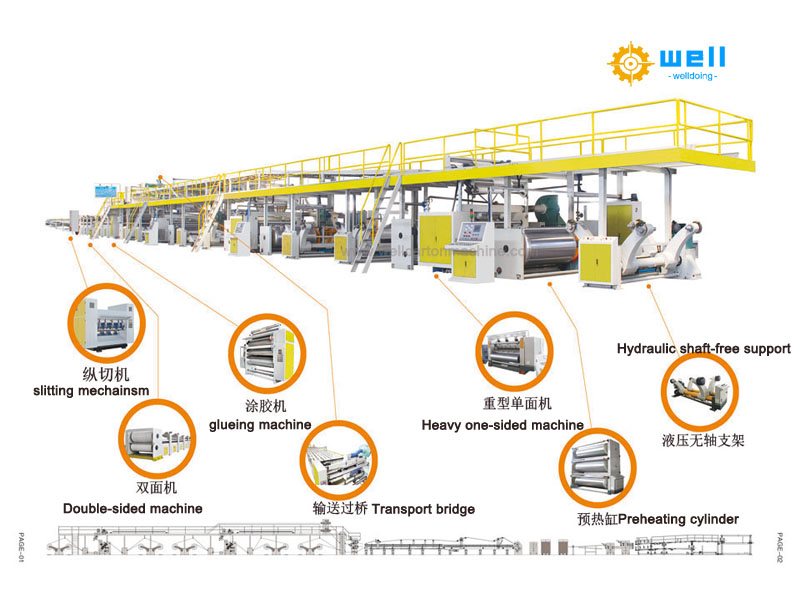

The 3/5 layer corrugated cardboard production line is suitable for mass automatic production. The paperboard meets the standard, the production efficiency is high, the paperboard quality is good, the centralized control is adopted, the operation is simple, the maintenance is convenient, the safety is reliable, and the labor intensity of the workers is greatly reduced. The production line adopts energy saving mode and provides heat source for the whole machine with high temperature heat conduction oil, which saves more than 40% of energy compared with other heating methods, greatly reduces energy consumption and effectively compresses production cost. It is an economical ideal product and is suitable for use in large and medium-sized carton factories.

Three-layer corrugated paperboard production line, five-layer corrugated board production line main features. :

High-quality chromium-base alloy steel is used for the material.

2.The corrugated shape is universal UV shape, after careful design, the shrinkage rate is low, the pressed paperboard is of good quality and high strength.

3.The imported precision machine tool, advanced molding grinding and computer grading technology are used to meet the standard.

4.The surface of the corrugated teeth is subjected to an intermediate frequency quenching treatment, and the upper corrugated roller has a middle height, a waist drum shape and a long service life.

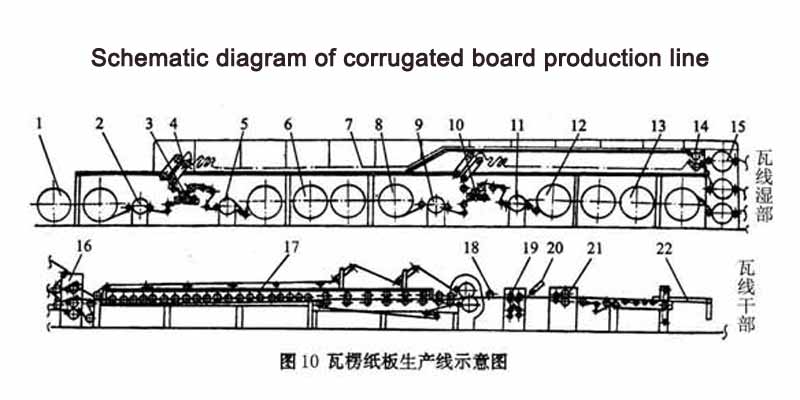

In 2005, the total length of corrugated board production line was 40 × 55 meters.

2.The total power of the whole machine is 55kw.

3.There are three types of shaft support, mechanical shaft-free support and hydraulic non-shaft support for customers to select.

4.Watt-hour machine: the diameter of the corrugated roller is 240-320 mm, and the electromagnetic speed-regulating motor is adopted.

5.Secondary glue spreader: the adjustment is convenient, and the glue spreading is uniform.

6.Dryer: the total length is 7.8 meters, 9 pieces of heating plate composition.

7.Shaping part: composed of a number of pairs of forming shafts, the total length is about 3.8 m.

8. Vertical, crosscutting machine: there are common and full computer models, blades can be installed according to user requirements of ultra-thin knife machine and ordinary knife machine, high degree of automation, easy to operate.

9.Boiler, coal consumption about 50 kg / h.

Technical parameters of three-layer and five-layer corrugated board production line:

| Shurang type | A | C | BC | B |

| Corrugated shape | UA | UA | UA | UA |

| Corrugated number | 34±2 | 38±2 | 46±2 | 50±2 |

| corrugated height | 4.6~5.0 | 3.6~3.9 | 3.0~3.5 | 2.6~2.9 |

| Outer diameter of roller body | 215~310 | 215~310 | 215~310 | 215~310 |

| barrel length | 1450~2050 | 1450~2050 | 1450~2050 | 1450~2050 |

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975