The intelligent advantages of paper angle edge board machines are mainly reflected in automated production, flexible customization, environmental performance, and efficient processing, which can significantly improve production efficiency and packaging quality.

automated production

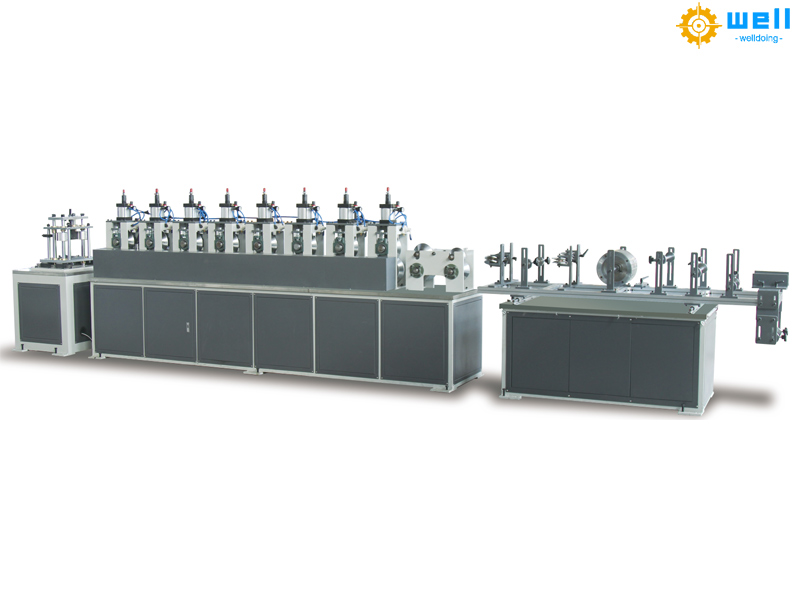

Modern paper corner protection equipment (such as the 100 type pulp paper corner protection production line) is equipped with modules such as paper guide, gluing, forming, cutting, and automatic stacking, achieving full process automation from raw materials to finished products, reducing manual intervention and lowering production costs.

Flexible customization

The paper corner protector production line supports adjusting the size according to customer needs (side length 25mm-90mm), and can produce right angle or "U" - shaped paper slots to meet the needs of different packaging scenarios.

Environmental Protection and Recyclability Paper angle board protector machine

Using water-soluble adhesive, the product can be recycled and reused, meets environmental requirements, and does not require fumigation treatment, making it suitable for export logistics.

High strength and impact resistance

Multi layer cardboard structure (such as 13 layers) enhances the load-bearing capacity of corner protectors (up to 1500KG), effectively protecting the edges of goods and reducing transportation losses.

cost-effectiveness

By automation and material recycling, packaging costs can be reduced while improving packaging firmness and minimizing the risk of logistics damage.

2. Equipment startup: According to the requirements of the Paper Tube Core Making Machine manual, start each device in sequence, observe the operation of the equipment, and ensure the normal operation of the equipment.

3. Paper winding: Place the paper on the unwinding device, adjust the paper tension, and make the paper smoothly enter the forming device. By adjusting the relevant parameters of the forming device, the paper is wound according to the preset shape and specifications.

4. Paper tube winding: Feed the wound paper into the winding device, and adjust the winding speed and pressure to tightly wind the paper into a paper tube.

5. Paper tube cutting: When the paper tube reaches the preset length, the cutting device will automatically cut off the paper tube. At this point, the operator can remove the cut paper tube and air dry it.

6. Equipment shutdown: At the end of production or when the paper core making machinery needs maintenance, according to the requirements of the equipment manual, turn off each device in sequence and disconnect the power supply.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975